The chemical industry finds itself at the pivot point of playing a key role in the development of new materials, processes and technologies which could result in it leading by example over climate change, despite itself being one of the world’s top contributors to global carbon dioxide emissions.

We look at chemistry’s vital role in our fight against climate change in our latest blog.

Looking beyond fossil fuels

While acknowledging that the industry remains heavily reliant on fossil fuels there is no denying that, properly harnessed, the chemical industry can be a key to increased resource efficiency, and improved quality of life.

While acknowledging that the industry remains heavily reliant on fossil fuels there is no denying that, properly harnessed, the chemical industry can be a key to increased resource efficiency, and improved quality of life.

We look at how we find ourselves in this position and some of the possible solutions in our new White Paper: Can Sustainability and Chemistry Coexist?

The 19th century saw a growing demand for chemicals to support industries such as fertilisers and pharmaceuticals.

Inevitably, coal was the primary source of energy during this time. It was the early 20th century when the chemical industry began to diversify its energy sources, shifting towards oil and natural gas.

The shift was driven by the development of new technologies and the realisation that petroleum-derived chemicals had several advantages over coal-derived chemicals, such as higher yields and lower production costs.

Now the need to move away from fossil fuels is gaining in urgency as the effects of climate change are being felt globally.

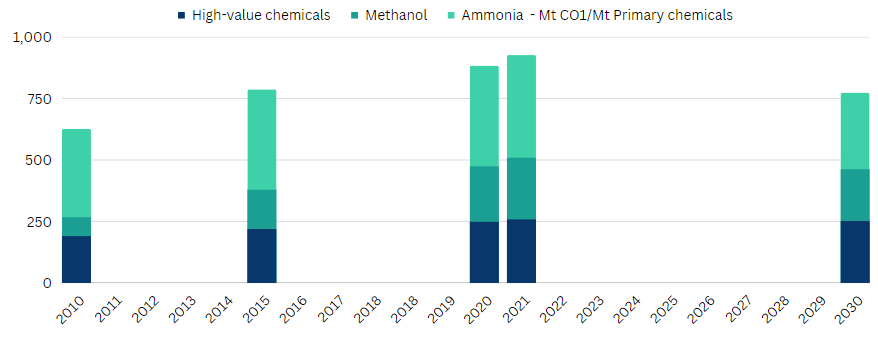

Carbon dioxide emissions: The Numbers

According to a report by the International Energy Agency (IEA, 2021), the chemical sector accounts for 7% or of global energy-related CO2 emissions.

In 2019, the sector emitted 1.2 billion tonnes of CO2, with the largest contributors being China (35%), the United States (14%) and the EU (9%).

The production of ammonia, ethylene, propylene and chlorine account for more than half of the industry’s CO2 emissions. The manufacturing of these chemicals involves energy-intensive processes, such as steam cracking, which requires large amounts of fossil fuels like natural gas or coal.

In recent decades ‘green’ chemistry has been involved in designing products and processes that minimise the use and generation of hazardous substances, leading to innovations such as biodegradable plastics, energy-efficient manufacturing processes and cleaner fuel alternatives.

In recent decades ‘green’ chemistry has been involved in designing products and processes that minimise the use and generation of hazardous substances, leading to innovations such as biodegradable plastics, energy-efficient manufacturing processes and cleaner fuel alternatives.

Chemistry is key to the development of renewable energy technologies, such as solar cells and batteries, for example. As efficiency and affordability of these technologies improves they can be a vital part of helping to reduce our dependence on non-renewable resources and decrease greenhouse gas emissions.

Rising to the green challenge

So can your company be one of those to pick up the gauntlet and help meet the challenges ahead?

Oxford Analytical has developed a 5-year plan to transform its workspaces into energy-efficient and environmentally friendly lab spaces.

The chemical industry has the potential to play a pivotal role in combating climate change. By embracing energy efficiency, investing in carbon capture and utilisation, developing sustainable materials, promoting circular economy principles, and fostering collaboration, the industry could contribute to a more sustainable future.

Oxford Analytical has demonstrated a firm commitment to the fight against climate change by implementing a holistic approach that encompasses multiple strategies, including a focus on sustainability, a comprehensive refurbishment plan, and a strong adherence to core values.

The start of our 5-year plan was to digitalise our work processes and this has reduced our paper footprint by 70% since 2021.

Measures have been introduced to recycle and extend expiry dates rather than dispose of chemicals.

Striving to meet high standards

Oxford Analytical is working on partnering with reputable waste suppliers accredited to ISO14001 to reduce the volume of waste we produce, and properly dispose of the waste we do produce to be recycled.

The company has adopted innovative technologies, such as energy-efficient LED lighting, solar panels, and low-energy HVAC systems. We have also prioritised waste reduction, recycling, and composting, in addition to encouraging employees to adopt eco-friendly commuting options, such as cycling or using public transportation.

Crucially we continue to research greener alternatives for use in sample preparation and ensure that any purchasing decisions we make are made with our sustainability values in mind. Our plans extend much further, including retrofitting the company’s buildings with energy-efficient systems and incorporating cutting-edge technology for waste and resource management.

By using sustainable materials and adopting green building principles, Oxford Analytical aims to achieve reduced energy consumption, lower greenhouse gas emissions, and minimise waste production.

We hope the company can serves as an inspiration and example for others in the industry to follow suit.

Company culture needs to encourage sustainability

Oxford Analytical inherently supports the chemical industry’s much-needed fight against climate change with the company’s existing service offering. Our original focus was on providing GLP-compliant pesticide residue analysis.

Now, with over 30 years of experience and sustained growth, we are able to offer a plethora of organically environment-inducing solutions such as biocides, bio-stimulants, and plant protection services. For example, plant protection may include practices such as environmental impact testing for soils and waters.

Recent examples of our work include a new novel plant protection product based on a natural biological micro-peptide, various other natural products such as those using Geraniol, essential oils such as peppermint oil and various amino acids such as those derived from seaweed.

By reviewing their current processes and infrastructure, businesses across the chemical industry could implement positive changes by instilling a company culture which encourages sustainable practices.

Conclusion

If businesses within the chemical industry can commit to the changes like these, as well as practices such as energy efficiency improvements, carbon capture utilisation, developing sustainable materials, circular economy, collaboration and partnerships, the industry will move from a sporadic climate change combatant to a prolific one.

Read more in our White Paper: Can Sustainability and Chemistry Coexist?